ORGANIC SEMICONDUCTORS ON PAPER FOR MOISTURE MONITORING IN NATURAL COMPOSITES

COMBINING 3D-PRINTING, DROP-CASTING AND SCREEN-PRINTING FOR RESIDUE-FREE SENSOR FABRICATION.

Continuously monitoring material moisture is essential for a widespread use of natural fiber-reinforced composite materials. The natural hygroscopicity of natural fibers and their degradation when exposed to high moisture levels for a longer time currently limits their use in load-bearing applications. The i³Sense project investigated how material-integrated condition monitoring can be implemented and, at the same time, focusing on natural, fiber-based materials for the preparation.

Paper as a carrier material offers the advantage that, when integrated into natural fiber composites, it is completely permeated by the low-viscosity resin, thus achieving optimal bonding to the surrounding material. In addition, the organic semiconductor Poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS), well-known for its high sensitivity to changes in relative air humidity, is suitable to be applied to paper substrates.

However, traditional micro-structuring processes, such as photolithography, are not compatible with paper substrates. Within i³Sense we developed an approach that makes it possible to manufacture sensors using simple, cost-effective methods. To do this, frame structures were printed onto a paper substrate using a 3D-printer, they were filled with the liquid semiconductor using drop casting and were then dried in the frame. The frame is removed afterwards. Electrical contact was established using a screen-printing process with flexible silver paste.

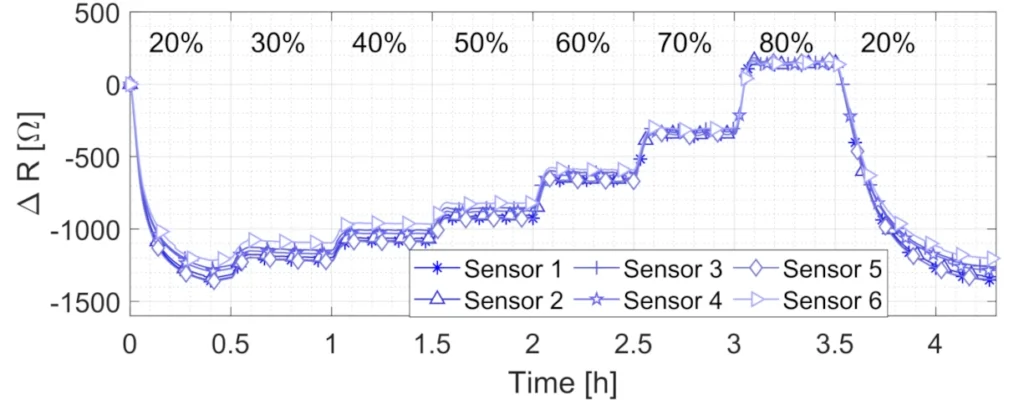

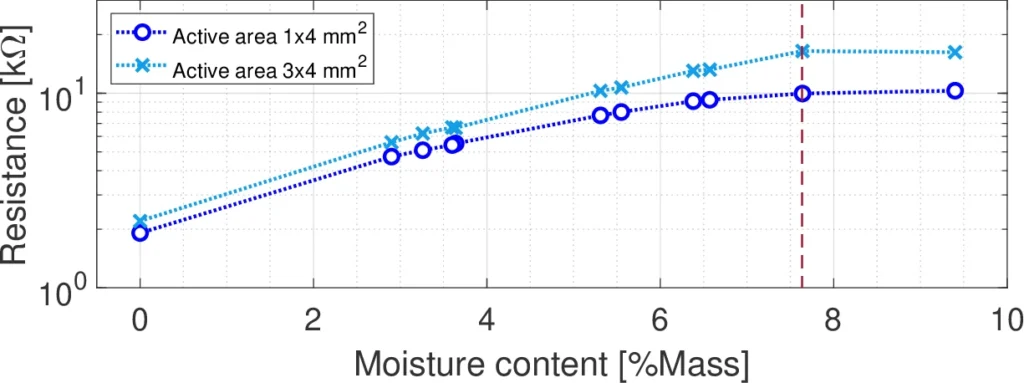

The sensors fabricated using this approach show a fast and reversible response to changes in relative humidity (Figure 1), as well as retaining full functionality and sensitivity after embedding into the composite. They show excellent performance especially at lower gravimetric material moisture contents (Figure 2). With this, they are well suited to detect early stages of water ingress into the material, preventing structural damage.

Impact and effects

Material moisture in natural fiber composites can reliably be detected using organic layers on paper. This approach represents a valuable step towards permanent monitoring of natural composites and contributes to making them more attractive as a nature-based construction material by increasing the long-term safety of the material through integrated monitoring. At the same time, paper as a sensor substrate results in an improved material adhesion inside the composite part.

Project partner

More details

Lead Partner:

Wood K plus - Kompetenzzentrum Holz GmbH

Project Management:

Priv.-Doz. DI Dr. Arunjunai Rai Mahendran

Project partners:

Universität Bremen, FACC AG, Fundermax GmbH

Funding Programme / Project ID:

FFG, KWF, Land NÖ, Land OÖ, BMIMI, BMWET

This success story was provided by the center management and by the mentioned project partners for the purpose of being published. Wood K plus is a COMET Center within the COMET – Competence Centers for Excellent Technologies Programme and funded by BMIMI, BMWET and the provinces of Carinthia, Lower Austria and Upper Austria. The COMET Programme is managed by FFG. Further information on COMET: www.ffg.at/comet